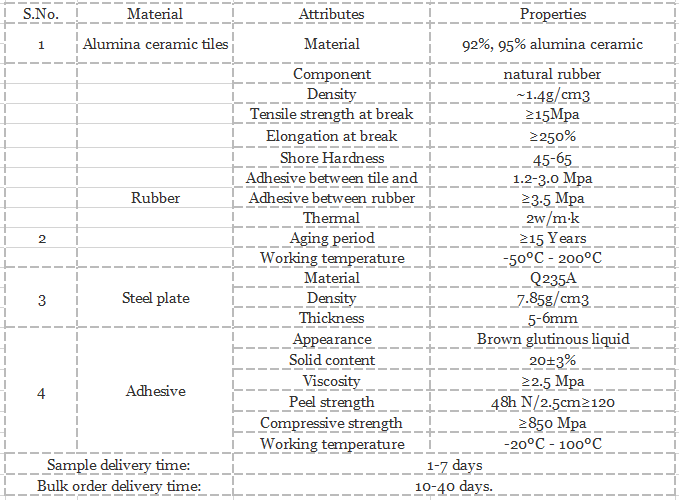

Wear Resistant Rubber Ceramic Lining Specifications

Intruduction

92% Al2O3 wear resistant rubber ceramic lining is made of high alumina ceramics and high quality natural rubber through special process. The excellent shock absorption properties of natural rubber can help achieve a certain impact resistance, thereby preventing the tiles from cracking in high impact areas, which is much better than ceramic lining tiles directly bonded to the steel structure. The hopper and chute with wear resistant rubber ceramic lining will be ten times longer.

Through vulcanization, alumina ceramic plates or alumina ceramic tiles are installed into special rubber (and steel) to form wear resistant rubber ceramic lining. The first type is Wear Resistant Rubber Ceramic Lining, which will be fixed to ceramic abrasives The equipment on the surface is made of high-strength adhesive, and the other type is rubber and steel-lined ceramic plates, which are composed of rubber, alumina ceramic plates and steel plates, which are fixed on the abrasive surface of the equipment by bolts welded on the steel plates.

Leading sizes of the Wear Resistant Rubber Ceramic Lining

| Sizes | Length/Width | Ceramic Thickness | Rubber Thickness | Steel Thickness |

| 250×250×15mm | 250/250mm | 5mm | 5mm | 5mm |

| 300×300×16mm | 300/300mm | 8mm | 4mm | 4mm |

| 500×500×25mm | 500/500mm | 15mm | 4mm | 6mm |

| 500×600×30mm | 500/600mm | 20mm | 6mm | 4mm |

| 600×300×35mm | 600/300mm | 25mm | 6mm | 4mm |

| 400×500×38mm | 400/500mm | 25mm | 7mm | 6mm |

| 300×400×50mm | 300/400mm | 30mm | 12mm | 8mm |

| 300×300×63mm | 300/300mm | 50mm | 7mm | 6mm |

| 300×400mm×130mm | 300/400mm | 100mm | 18mm | 12mm |

Applications

XR GROUP’s Wear Resistant Rubber Ceramic Lining / board / lining pad as a wear protection solution for funnels has been widely used in harsh abrasive environments such as chute lining, cyclone lining, conveyor skirt lining, processing pipe lining, hopper or silo Lining, lining of screening equipment includes but is not limited to: coal preparation plants, coal-fired power plants, beneficiation plants, cement plants, steel plants, railway stations and ports.

WELCOME TO CONTACT US!!!

https://www.linkedin.com/company/43241093/admin/

https://www.facebook.com/XR-GROUP-103856021379236

Tel/whatsapp:+8618766918053

skype:florahu11