Introduction

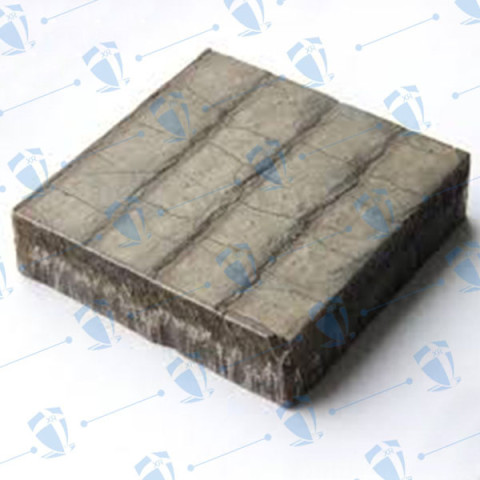

Product Name:Wear Bimetal Cco Plate

Material:Q235B carbon steel plate+Wear Bimetal Cco Plate

Thickness:3+3,6+4,8+4,6+6,8+6, 12+8, 10+10,12+12,etc.Or as your requirement.

Hardness:58-63 HRC

Surface Treatment: Hardfacing , clading ,coated.

Technique:Bibetal hardfacing

Chemical Composition: C : 4.0-5.0%,Cr : 20-45%,Mn : 1.0-5%

Base Plate:Q235 / Q345

Plate Size:Length: 3000mm,Width: 600-1500mm,Sizes are customised as requests

MOQ:even there quantities are less,we will also try best to help

Feature:

(1)XR GROUP’s Wear Bimetal Cco Plate with high wear resistance

(2)12-20 times higher than common plate

(3)5-10 times than low alloy steel plate

(4)2-3 times than high chromium cast iron plate

Specifications

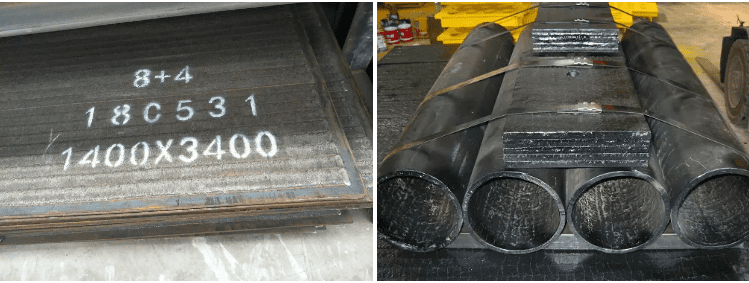

|

Plate Size |

1400*3400,1400*3500,also customised |

| Hardness | 58-65HRC |

| Si | 0.5%-1.5% |

| Mn | 0.5%-2.5% |

| C | 4% |

| Surface Cr % | 20%-30% |

| Others | less 2% |

Features:

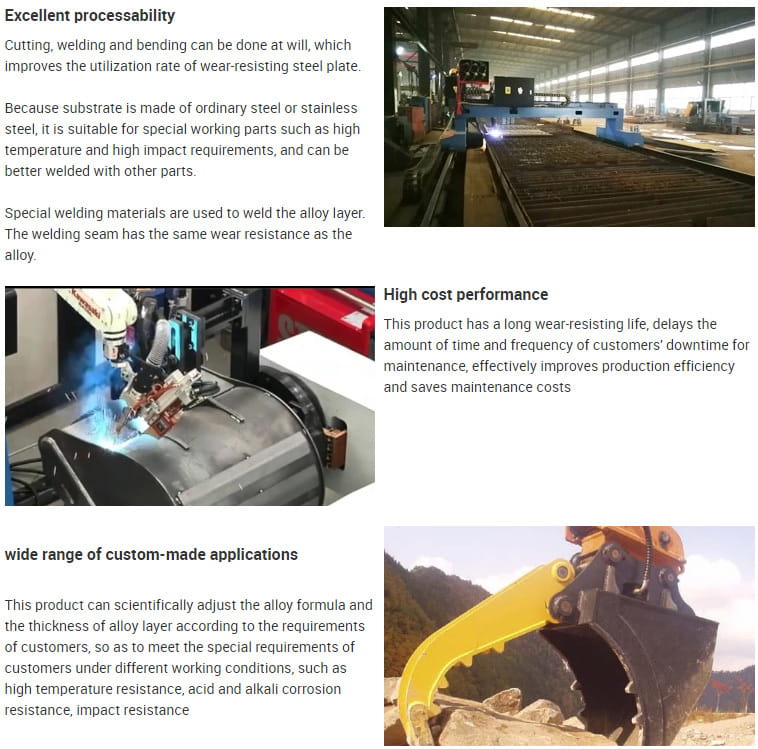

1.Compared with low carbon steel plates,chromium carbide overlay plate with higher hardness and excellent wear resistance.

2.Chromium carbide oveerlay plate useful life is more 10 times than low carbon steel plates.

3.Easy installation, cutting, welding, punching, bending.

4.Chromium carbide overlay plate can bear high temperature to 500 degree.

1. The overlay chemical composition is the key

The main ingredients of XR GROUP‘s Wear Bimetal Cco Plate are C(%) :3.0-5.0 and Cr(%):25-40. This chemical proportion results in a large amount of Cr7C3 chrome carbide hard particles. The micro-hardness (up to HV1800) of these particles throughout the layer will guarantee a super wear resistant surface.

Performance test:

Test equipment: Quartz sand rubber wheel abrasion test machine.

Conditions: Choosing same dimension specimens for different materials and wear plate producers, and put them under the same wearing working conditions in our testing equipment.

WELCOME TO CONTACT US!!!

https://www.facebook.com/XR-GROUP-103856021379236

https://www.linkedin.com/company/43241093/admin/

Tel/whatsapp:+8618766918053

skype:florahu11

Email:sales01@xrwearresistant.com