Description

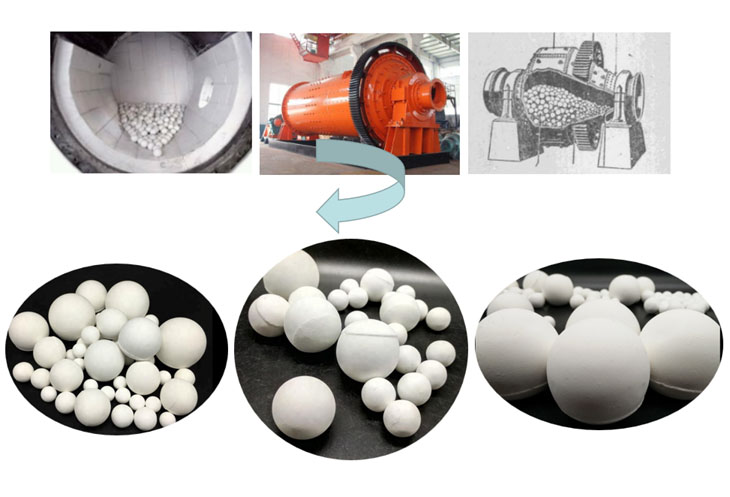

Wear-resistant alumina grinding ball is a high-quality grinding medium, made of selected high-grade materials, advanced molding technology, and calcined in high temperature tunnel kiln. Ceramic Alumina Grinding Ball has high density, high hardness, low abrasion, good seismic stability and good corrosion resistance. It is the most ideal medium for the processing of abrasive glazes, blanks and mineral powders, and is used as ceramics, cement, coatings, refractory materials , Inorganic mineral powder and other industries.

Able to manufacture products with different specifications according to customer requirements.

The wear resistance of the Ceramic Alumina Grinding Ball is higher than that of ordinary alumina balls. It will not pollute the grinding materials during work, so it can maintain purity and improve the stability of the grinding materials, especially ceramic glaze.

XR GROUP’s Alumina ceramic grinding ball with high density, high density, high hardness and high grinding characteristics save grinding time and expand the crushing space. Therefore, the polishing efficiency can be improved.

Charactures

1) Alumina ceramic grinding ball is an ideal grinding medium for ball mills, which can maintain purity and improve the stability of grinding materials.

2) Alumina grinding balls have been widely used in ball mills as grinding media for ceramic raw materials and glazes in ceramic factories, cement factories, enamel factories and glass factories.

3) The main features of the Ceramic Alumina Grinding Ball with high density, high hardness and strength, high wear resistance, thermal stability, corrosion resistance and non-pollution.

4) During the grinding/grinding process, the Ceramic Alumina Grinding Ball will not break or contaminate the material to be ground.

5) Type: According to Ceramic Alumina Grinding Ball content: 60-70%, 65-75%, 95%, 95%

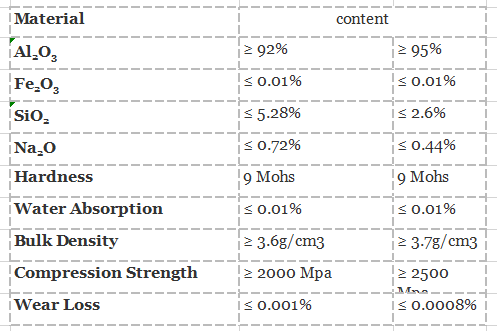

Ceramic Alumina Grinding Ball Technical details

Generally, Alumina ceramic grinding balls are packed in sturdy double PP bags, tied and shrink-wrapped with pallets for better preservation, and ready for immediate delivery.

Packing

Standard packaging is 25 kg/bag, 1-1.5 tons/pallet, 20-25 tons/20′ container.

*Customized packaging may be provided upon request, additional charges collect.

Features

♦High hardness is second only to diamond

♦Reduce wear

♦ Standardized

♦Good corrosion resistance

♦Higher grinding efficiency

♦No pollution

♦Long service life

Welcome to contact us!!!

https://www.facebook.com/XR-GROUP-103856021379236

https://www.linkedin.com/company/43241093/admin/

Email:sales01@xrwearresistant.com

Te/whatsapp:+8618766918053