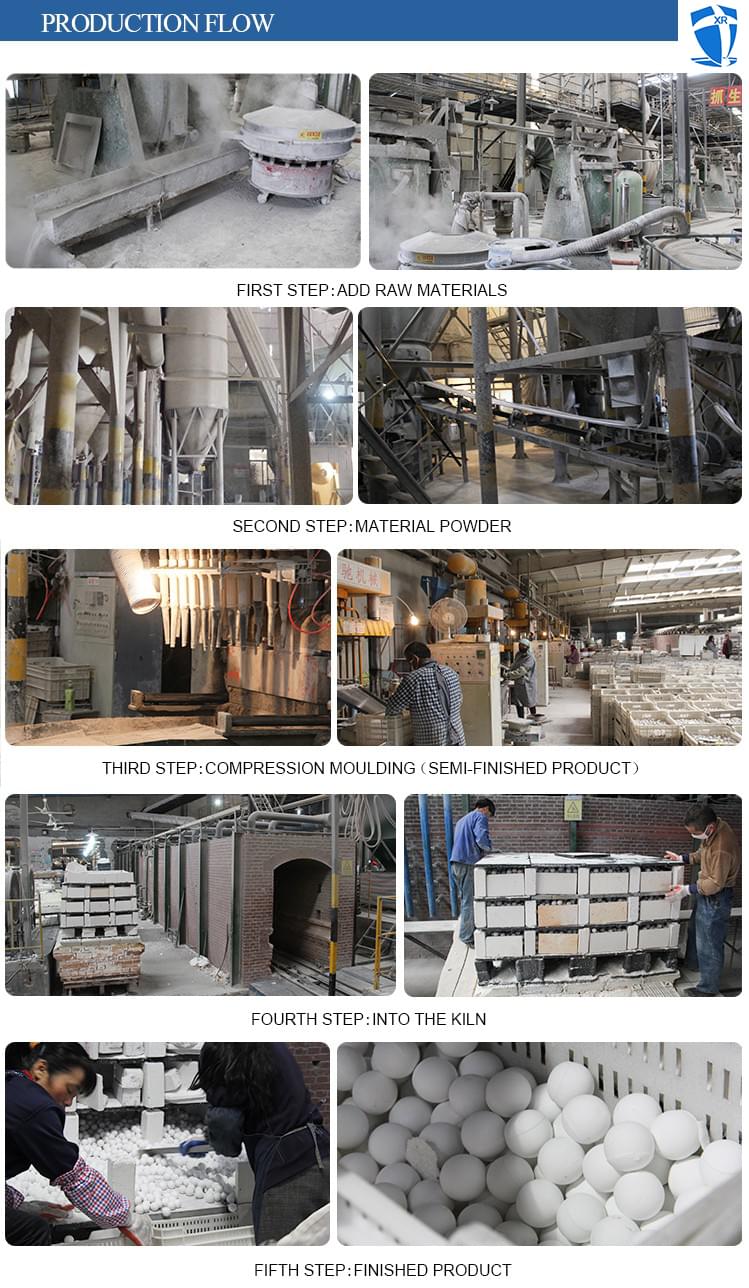

Introduction

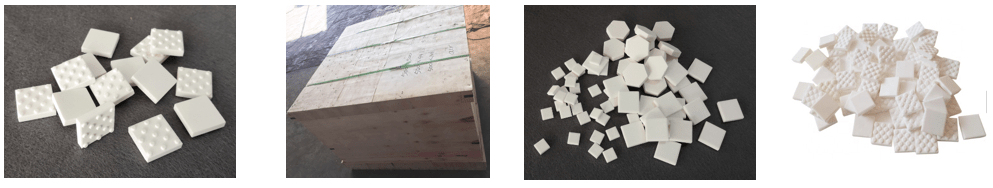

XR produces and stocks a full range of high-density, fine-grain, Alumina ceramic mosaic tiles.

Alumina ceramic is next to diamond in hardness, is 12 times more wear-resistant than carbon steel, and exhibits excellent corrosion-resistance.

Wear-resistant tiles prevent erosion and abrasive wear in conveying and bulk material handling systems, as well as in piping systems.

Properties:

Chemical resistant

Mechanical erosion & Abrasion resistant

Electrically insulative

Replaceable

Specifications

| Name | Alumina ceramic mosaic tiles |

|

Feature |

l Rockwell hardness is HRA80-90.l Alumina ceramic mosaic tiles with Wear Resistant limit is 266 times manganese steel and 171.5 times chromium cast iron.Alumina ceramic mosaic tiles works normal and well under 1450℃.l Good impact resistance: unique formula applied to strengthen crystal bond and the impact resistance has be substantially improved.l Half the steel density and Smooth surface. |

|

Application |

coal conveying system, material feeding system, powder pulverizing system, ash discharging system, dust removal system, etc. for industries of thermal plant, steel, Metallurgical Plant, mechanical, coal, mining, petrochemical, cement, port, and so on. |

Our products mainly have the follows catalogue:

1. Alumina ceramic mosaic tiles

2. Alumina Ceramic Lining Bricks;

3.Alumina Ceramic Lined Steel Pipelines & Rubber Lined Steel Pipeline

4.Composite Rubber Ceramic Lining Plate;

5.Alumina Ceramic Balls;

Advantages

1) A variety of specifications available.

2) Satisfy various technical request

3) Lower medium spoilage

4) Good insulation performance and high temperature resistance

5) Excellent wear resistance

Shipping and packing

WELCOME TO CONTACT US!!!

https://www.facebook.com/XR-GROUP-103856021379236

https://www.linkedin.com/company/43241093/admin/

Tel/whatsapp:+8618766918053