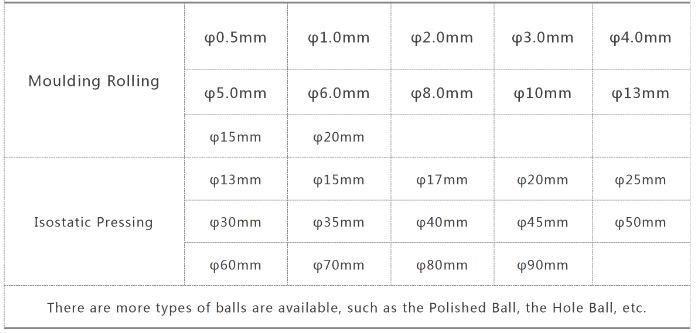

XR GROUP Alumina ceramic Beads leading sizes

Description

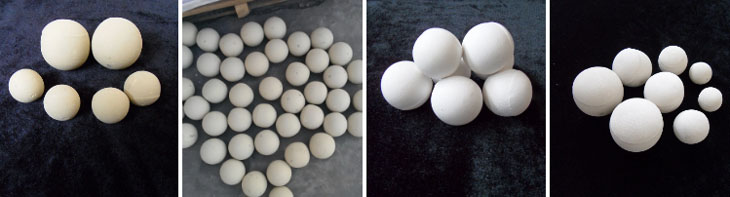

Alumina ceramic grinding ball is a non-metal grinding medium that is widely used in industrial grinding.

There are many physical and chemical advantages that are different from metal grinding balls,Today I will introduce his features and applications. Alumina ceramic Beads are made from high-purity alumina powder after isostatic pressing and high temperature sintering.

The density of 92 alumina balls is about 3.6 cm3, the Mohs hardness is grade 9, the water absorption rate is close to 0, and the self-wear rate is 0.01%.

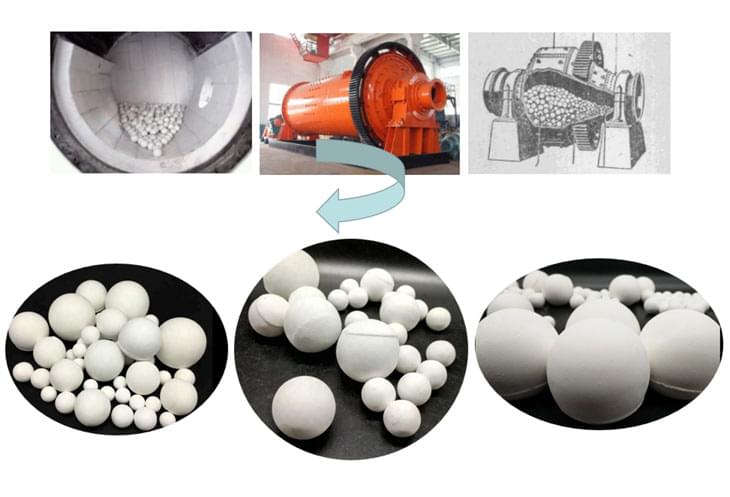

Glass grinding. First, the hardness of glass is very high. The processing capacity of ordinary grinding media is limited. Containing too many impurities will greatly reduce the quality of the glass, resulting in poor quality of the finished glass, which makes it impossible to produce high-quality products. The Alumina ceramic Beads can solve this problem well.

For the grinding of quartz, the hardness of the same quartz is also very high, especially the high white quartz has high requirements for whiteness. The color of Alumina ceramic Beads are only white, which solves the grinding problem of high white quartz from many aspects.

Cement grinding is a very popular industry in recent years. Alumina ceramic Beads have extremely low wear resistance, thermal conductivity and low density characteristics. The effect of improving product quality is obvious.

Alumina ceramic balls can use their own materials. We know that lithium battery materials are very sensitive to iron, so no metal grinding is used. Alumina is not a metal grinding medium, but the most effective method of Alumina ceramic Beads. Therefore, when people are not allowed to use alumina, he has become a grinding material.

Charactures

1) Sphere (ball) or cylinder.

2) Very good support and media coverage.

3) Used as a supporting medium for catalyst beds or other chemical beds in reactors or towers.

4) Excellent performance and stability in acidic and other chemical environments.

5) Good chemical stability and low water absorption.

6) Can withstand high pressure and high temperature.

7) Alumina ceramic Beads can even be used in hot caustic environments because they can withstand the use of more than 10% sodium hydroxide at 60% high temperature and 1% sodium hydroxide at 100°C.

8) It can also resist any acid (including organic and inorganic acids, except HF acid), chemical corrosion of most alkali and organic solvents.

9) It will increase the distribution of liquids and gases, support and protect the catalyst, and avoid poisoning.

Alumina Ceramic Beads Processing

Why choose XR GROUP?

With manufacuture price.

Professional engineers in our company.

Returned money if any quality problems.

Free samples are provided.

Welcome to contact us!!!

https://www.facebook.com/XR-GROUP-103856021379236

https://www.linkedin.com/company/43241093/admin/

Tel/whatapp:+8618766918053

Email:sales01@xrwearresistant.com