Features

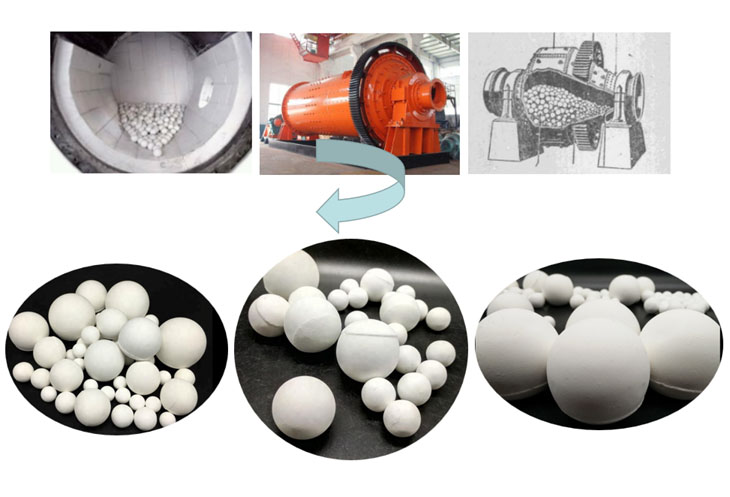

1) XR GROUP’S Alumina ceramic balls are the ideal grinding medium for ball mills, which can maintain purity and improve the stability of grinding materials.

2) Alumina grinding balls have been widely used as abrasives for ceramic raw materials, glazes, ceramic factories, cement factories, enamel factories and glass products in ball mills.

3) The main features are high density, high hardness and strength, high abrasion resistance, thermal stability, corrosion resistance and no pollution.

4) During the grinding process, Alumina ceramic balls will not break and will not contaminate the material to be ground.

5) Type: According to alumina content: 60-70%, 65-75%, 95%, 95%

Alumina ceramic balls Technical datas

This method is a domestic test method in which alumina ball samples are put into polyurethane tanks to test the amount of wear per unit time.

- Pour 4kg of alumina balls and 4L of water into a grinding tank, put it into a testing machine, and grind it at 80r / min for 2h. The sample was taken out and dried and weighed M1.

- Put the above sample into the jar again, add 4L of water, and grind it for 24h at 80r / min.

- Remove the dried sample and obtain the weight of M2.

- Test the average diameter of the sample to get the average diameter D5.

Calculation of wear loss: EWT (% o) = KD M 1-M2) M 1

Empirical formula: EWT (% o) = (M1-M2) M1 / 24/100 * 1000 * D

Alumina ceramic balls uses

Packing details

Welcome to contact us!

https://www.facebook.com/XR-GROUP-103856021379236

https://www.linkedin.com/company/43241093/admin/

Tel/whatsapp:+8618766918053

skype:florahu11