Breif Introduction

Bimetal welding wear resistant alloy steel plate/Wear Resistant Bimetallic plate, its substrate using common Q235B steel plate, and Wear-resisting layer is composed of advanced alloy welding which was joint research and development by our company and scientific research institutions.

Specifications

1. The overlay chemical composition is the key

The main ingredients of the wear resistant bimetallic plates are C(%) :3.0-5.0 and Cr(%):25-40. This chemical proportion results in a large amount of Cr7C3 chrome carbide hard particles. The micro-hardness (up to HV1800) of these particles throughout the layer will guarantee a super wear resistant surface.

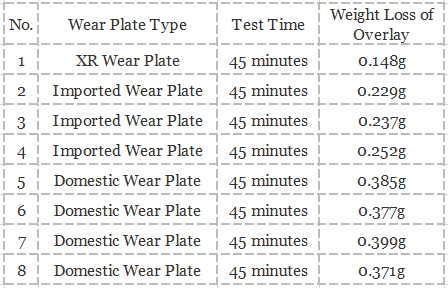

Performance test:

Test equipment: Quartz sand rubber wheel abrasion test machine.

Conditions: Choosing same dimension specimens for different materials and wear plate producers, and put them under the same wearing working conditions in our testing equipment.

45 minutes for each specimen.

Results: The test results show that the life span of Wodon wear plate is 2.5 times higher than domestic wear plates and 1.5 times than imported ones.

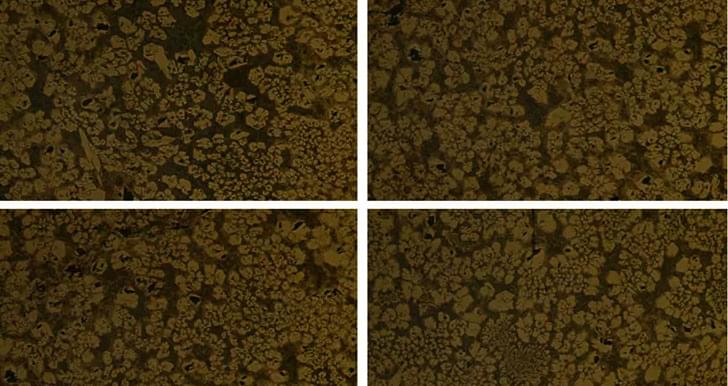

2.Wear Resistant Bimetallic plate microstructure

The wear resistance of Wear Resistant Bimetallic plate depends mostly on the hardness, shape, size, amount and distribution of the chromium carbide hard particles.

As you can check on the picture, the carbide (Cr7C3) volume fraction on the microstructure is above 50%.

3. Bonding strength between the overlay and base plate.

The overlay and base plate are very well bonding. The overlay will penetrate into base plate about 0.8mm-1.8mm, reaching up to 350Mpa in our tests.

Packing Details

Welcome to contact us!

https://www.facebook.com/XR-GROUP-103856021379236

https://www.linkedin.com/company/43241093/admin/

Tel/whatsapp:+8618766918053

skype:florahu11