Breif Introduction

Silicon Carbide Plates was originally produced by a high temperature electro-chemical reaction of sand and carbon. Silicon carbide is an excellent abrasive and and made into grinding wheels and other abrasive products. Today the material has been developed into a high quality technical grade ceramic with very good mechanical properties. It is used in abrasives, refractories, ceramics, and a large number of high-performance applications. Silicon Carbide can also be made an electrical conductor and has applications in resistance heating, flame igniters and electronic components.

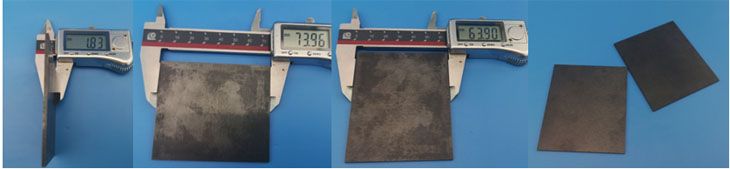

Technical datasheet

| Item | Unit | Silicon Carbide /SiC |

| Purity | % | ≥99% |

| Volume density | g/cm 3 | 3.13 |

| Coefficient of heat expansion | 1×10 -6 | 4.0 |

| Bending Strength | Mpa | >400 |

| Hardness | HRA | 92-94 |

| Max Use Temperature | ℃ | 1650 |

| Thermal conductivity | W/(m.k) | 120-150 |

| Compressive strength | / | >2200 |

Features of the Silicon Carbide

1. High effeciency of heat-conduction

2. Heat shock stablity

3. Wear resistant

4. High temper-endure(up to 1200deg-1600deg)

5. Self-lubrication

6. High performance of mechanical strength

7. Chemical corrosion-resistant

Silicon Carbide Small Wear Resistant Parts, Silicon Carbide Wear-Resisting parts For the Most Difficult Applications

• Extreme Hardness and High Strength

• High Abrasion and Wear Resistance

• Excellent Corrosion Resistance

• Superior Thermal Shock Resistance

providing high performance materials that have proven successful in a wide variety of applications and pump design types including:

• Gear Pumps

• Magnetically-driven Pumps

• Canned Motor Pumps

• Multi-stage Pumps

• Vertical Pumps

• Down Hole Pumps

Property

Superior high temperature resistance,wear resistance and oxidation resistance.

Excellent straightness,less than 1‰.

High uniformly distributed loading capacity,more than 4997 kg.m/L.

OEM accepted.

Easy to install.

Various shape accepted,Germany imported technology and materials.

Longer service life ( about 5 times more than that of alumina ceramic and 6 times more than that of polyurethane).