Wear Hardfacing Plate Introduction

Wear Hardfacing Plate is mainly composed of chromium alloy, and other alloy components such as manganese, molybdenum, niobium, and nickel are also added. The carbides in the metallographic structure are distributed in a fibrous shape, and the fiber direction is perpendicular to the surface. Carbide microhardness can reach HV1700-2000 and surface hardness can reach HRC 58-62. Wear Hardfacing Plate has strong stability at high temperatures, maintain high hardness, and also have good anti-oxidation properties.Wear Hardfacing Plates are fully used within 5000C.

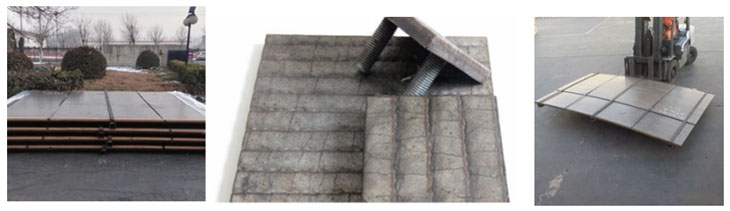

Wear Hardfacing Plate has high wear resistance and good impact performance. Wear Hardfacing Plate can be cut, bent, welded, etc. It can be connected to other structures by welding, plug welding, bolting, etc., which saves time during the maintenance site process. And convenience, widely used in metallurgy, coal, cement, electricity, glass, mining, building materials, bricks and other industries.

Specifications of the chromium carbide plates

1. Wear-resistant steel plate:

Medium / low carbon steel + wear-resistant layer → wear-resistant steel plate with metallurgical bonding

(Q235 / Q345B + chrome carbide coating → chromium carbide wear plate with submerged arc welding or open arc welding)

2. Process:

Various liners are made of Wear Hardfacing Plate by cutting, bending, stamping, bolting and welding.

According to customer drawings.

3. Standard size: up to 2400 * 4000 mm, without slits, customer requirements

Open-arc welded plate: 1.4 m * 3.4 m, custom-made

Submerged arc welding plate: 1.4 m * 3.0 m, 1.4 m * 3.5 m, 2.1 m * 3.5 m, can be customized

4. Certification: ISO 9001: 2008

5. Details:

The surfacing alloy has a large number of chromium carbide hard particles. These Wear Hardfacing Plate particles are evenly distributed throughout the layer, forming a strong microstructure. The hardness is HRC 55 ~ 65, depending on the thickness of the cover.

Characters

The chemical composition of the alloy wear layer has a carbon content of 4 to 5% and a chromium content of 25 to 30%. The volume fraction of Cr7C3 carbides in the metallurgical structure is more than 50%. The macro hardness is HRC56 to 62. The hardness is HV1400 ~ 1800. Because the carbides are distributed vertically in the wear direction, the wear resistance is more than doubled, even when compared with a cast alloy of the same composition and hardness. Compared with several typical materials, the Wear Hardfacing Plate wear resistance is as follows:

(1) with low carbon steel; 20 ~ 25: 1

(2) with as-cast high chromium cast iron; 1.5 ~ 2.5: 1

Welcome to contact us!

https://www.facebook.com/XR-GROUP-103856021379236

https://www.linkedin.com/company/43241093/admin/

Tel/whatsapp:+8618766918053

skype:florahu11