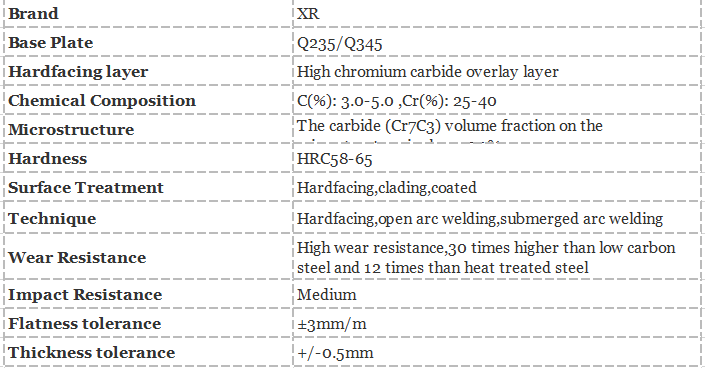

Specifications

What can we do!?

1. Drilling Holes

Straight holes and Countersunk holes of the Chrome Carbide Plate

2. Bolt embedded welding in the back

Embedding the pre-processed bolt in the back of chrome carbide plate.

3. Bending

Chrome carbide overlay plates can be cold formed and made into curve of cone.

4. Welding

Wear carbide overlay plate can be welded and assembled into kinds of Chrome Carbide Plate

Packing Details

FAQ

Q1: Why are there so many cracks?

A1. Due to the cooling rates of dissimilar metals. Our hard facing plate for coal chute liner is manufactured bywelding which results in high temperatures. During the cooling, Chrome Carbide Plate goes through a stress relieving which is a natural process and does not effect the performance of the plate. The stress relief cracks should be between 3/4″ – 2″ apart. The cracks can be touched up by our chrome carbide welding rod.

Q2: What is the best method of attachment?

A2. hard facing plate for coal chute liner is usually attached by countersunk bolts, welding studs, perimeter welding, or plug welding. Some methods are better suited than others depending on the specific application. For more detail on each method see the installation section.

Q3: Can hard facing plate for coal chute liner be drilled or machined?

A3. hard facing plate for coal chute liner cannot be machined or drilled. It can however be ground. Mild steel inserts are used to create countersunk or counter bored holes. hard facing plate for coal chute liner can be cut using plasma, Grinding wheel saw, or air-arc gouging.

Q4:MOQ?

A4.Our product has no limit to quantity, it can be ordered according to customer requirement.

Q5: What’s the service life compare with Hardox series?

A5.Generally speaking, our bimetallic overlay wear plate is 4.5~8 times than Hardox series in service life.

Welcome to contact us!

https://www.facebook.com/XR-GROUP-103856021379236

https://www.linkedin.com/company/43241093/admin/

Tel/whatsapp:+8618766918053

skype:florahu11